Large 3D printers are changing the game for creators and manufacturers alike. These machines can produce big objects that were once impossible to print at home or in small workshops. Large format 3D printers can build items up to 500 x 500 x 500 mm or even larger, opening up new possibilities for prototyping, custom manufacturing, and artistic expression.

You might wonder why you’d need such a big printer. Think about making full-size furniture parts, large architectural models, or even life-size props for movies. These printers let you dream big and bring those ideas to life. Plus, they’re not just for pros anymore – some models are now affordable for hobbyists too.

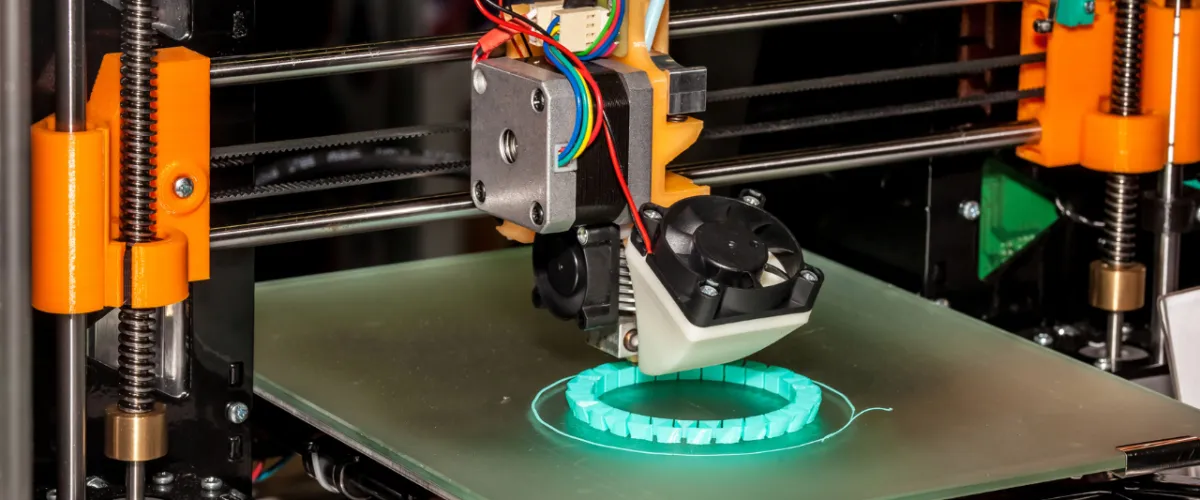

When picking a large 3D printer, you’ll need to consider build volume, print speed, and material compatibility. Some printers use FDM technology, melting plastic filament to build objects layer by layer. Others use resin-based methods like stereolithography for smoother finishes. Your choice depends on what you plan to make and how much detail you need.

Key Takeaways

- Large 3D printers can create objects up to 500 x 500 x 500 mm or bigger

- These printers use various technologies like FDM and stereolithography

- Consider build volume, print speed, and materials when choosing a large 3D printer

Understanding Large Format 3D Printers

Large format 3D printers open up new possibilities for creating big objects. These machines can make large parts for industries like aerospace, automotive, and construction.

Defining the Large Format in 3D Printing

Large format 3D printers have bigger build volumes than standard desktop printers. Most have print areas over 30 cm (11.8 in) in at least one dimension. Some can even print objects several meters tall!

You might wonder, “How big is big?” Well, imagine printing a life-size statue or a full-size car bumper. That’s what these printers can do.

Large format doesn’t just mean size. It also refers to the printer’s ability to handle industrial-grade materials and produce high-quality, durable parts.

Technologies Behind Large Format 3D Printing

Large format printers use different technologies to create big objects. The most common are:

- Fused Filament Fabrication (FFF): This method melts plastic filament and builds objects layer by layer.

- Stereolithography (SLA): Uses a laser to cure liquid resin into solid parts.

- Selective Laser Sintering (SLS): Fuses powder materials with a laser to create objects.

Each technology has its strengths. FFF is great for affordable, large-scale printing. SLA offers smooth surfaces and fine details. SLS can make strong, functional parts.

Have you ever seen a 3D-printed boat? That’s the power of large format printing!

Advantages of Large Format 3D Printing

Large format 3D printing brings big benefits to many industries. Here are some key advantages:

- Rapid prototyping of large parts

- Cost-effective production of custom, one-off items

- Ability to create complex geometries impossible with traditional methods

- Reduced material waste compared to subtractive manufacturing

Imagine you’re designing a new car. With a large format printer, you can quickly make full-size prototypes of body panels or interior components. This speeds up the design process and saves money on tooling costs.

Large format printing also shines in architecture. You can print detailed building models or even full-scale furniture pieces. The possibilities are as big as your imagination!

Key Components of Large 3D Printers

Large 3D printers have several crucial parts that work together to create big objects. These components determine how well the printer performs and what it can make.

The Extruder and Nozzle Mechanics

The extruder is the heart of your large 3D printer. It pushes the filament through the nozzle. For big prints, you need a strong extruder that can handle long print times.

Most large printers use direct drive extruders. These give you more control over the filament flow. The nozzle size is also important. Bigger nozzles (0.6mm to 1.2mm) let you print faster, but with less detail.

Heat management is crucial in large printers. The QIDI MAX3 3D Printer has a heated chamber to help with this. It keeps the whole print area warm, which is great for big objects.

Types of 3D Printing Filament

Your choice of filament affects what you can print and how it turns out. For large prints, you need strong materials that don’t warp easily.

PLA is good for beginners, but it’s not very strong. ABS and PETG are tougher and work well for big objects. Some printers can use composite filaments with wood or metal particles mixed in.

Flexible filaments like TPU are tricky in large printers. They need special extruders to work well. For the biggest and toughest prints, you might use engineering-grade plastics like nylon or polycarbonate.

Printer Bed and Build Volume Considerations

The build volume is what sets large printers apart. It’s how big of an object you can make. Some printers, like the Creality CR-M4, offer huge build volumes of 450x450x470mm.

Your print bed needs to be flat and stick well to the first layer. Many large printers use glass beds or flexible steel sheets. Bed leveling is super important for big prints. Auto-leveling features help a lot here.

Heated beds are a must for large printers. They help prevent warping in big prints. Some printers even heat the whole chamber to keep everything at the right temperature.

Support Structures and Print Reliability

Big prints often need support structures. These hold up parts of your print that would otherwise sag or fall. Good slicing software can generate smart supports that are easy to remove.

Reliability is key for large prints that take days to finish. You need a printer that won’t fail halfway through. Look for features like filament sensors that pause the print if you run out of material.

Cooling is also crucial for reliability. Large printers need powerful fans to cool each layer quickly. This helps prevent sagging and improves overall print quality.

Software and User Interface for Large Scale Printing

Using the right software and interface is key for successful large-scale 3D printing. The right tools can make or break your project.

Importance of Software in 3D Printing

Good software is vital for big 3D prints. It helps you design, prepare, and print large objects with ease. BLADE, a slicer made for large-format printing, shows how tailored software can boost efficiency. It cuts print times and saves materials.

You’ll find that the best software for large prints offers:

- Easy scaling of models

- Smart support generation

- Efficient slicing for big objects

Have you ever tried to print something huge only to have it fail halfway through? Good software can help avoid that headache.

Challenges in Large Scale 3D Model Preparation

Preparing big 3D models isn’t always a walk in the park. You might face issues like:

- Long processing times

- Computer memory limits

- Complex support structures

Luban 3D is a tool that can help you tackle these hurdles. It’s made to handle large-scale projects.

Think about the last time you tried to open a huge 3D file. Did your computer slow to a crawl? That’s where specialized software comes in handy.

File Formats and Software Prototyping

Choosing the right file format is crucial for large prints. STL is common, but for big projects, you might want to look at:

- OBJ: Good for color and texture

- 3MF: Newer format with better data compression

- AMF: Supports multiple materials and colors

For prototyping, you need software that can handle tweaks and changes quickly. Professional 3D printers often come with intuitive interfaces that make prototyping a breeze.

Have you ever had to redo a print because of a tiny change? Good prototyping software can save you time and materials.

Operational Considerations and Maintenance

Large 3D printers require careful attention to detail for smooth operation. Regular upkeep and safety protocols are key to getting the most out of these machines. Let’s explore how to keep your big printer running reliably and safely.

Ensuring Reliable Operation of Large 3D Printers

You’ll want to start by checking the belt tension regularly. Loose belts can cause poor print quality. Keep an eye on your printer’s moving parts too. Apply a drop of light machine oil to keep things running smoothly.

Clean your printer often. Dust can build up quickly, especially around fans and the extruder. A clean printer is a happy printer!

Make sure to level your print bed before each job. This step is crucial for large prints. You might consider using a sensor to automate this process.

Don’t forget about your printer’s firmware. Keep it updated to benefit from the latest features and bug fixes.

Maintenance Protocols and Warranty Information

Create a maintenance schedule and stick to it. This helps catch issues before they become big problems.

Here’s a simple maintenance checklist:

- Clean the print bed after each use

- Check and tighten screws monthly

- Lubricate moving parts every 3 months

- Replace worn parts as needed

Keep your extruder clean for the best print quality. A clogged nozzle can ruin your day!

Read your warranty carefully. Some actions might void it. Keep records of all maintenance you perform. This can be helpful if you need warranty service.

Materials and Safety in Large Scale 3D Printing

Choose your materials wisely. Not all filaments are created equal. Some produce fumes, so good ventilation is a must.

Consider these safety tips:

- Wear gloves when handling hot parts

- Use safety glasses to protect your eyes

- Keep a fire extinguisher nearby

Heat is a big factor in large 3D printing. Make sure your printer has good cooling systems. This helps prevent warping and other heat-related issues.

Carbon fiber filaments are popular for large prints. They’re strong but can be abrasive. Use a hardened steel nozzle if you print with these materials often.

Remember, safety first! Large printers have more moving parts and hotter temperatures. Stay alert and follow all safety guidelines.

Conclusion

Large 3D printers have changed the game in manufacturing. They let you create big, complex objects that were hard to make before. From huge aerospace parts to life-size sculptures, the possibilities are exciting.

You might wonder if these printers are worth it. Think about what you could make with a build volume of 600 x 300 x 300 mm. That’s big enough for furniture pieces or industrial prototypes.

But it’s not just about size. Large 3D printers often come with cool features:

- Auto-leveling beds

- Dual extruders

- High-temp capabilities

These make your printing easier and more versatile.

Have you considered the impact on different industries? Healthcare, construction, and even fashion are using large-scale 3D printing in innovative ways.

Sure, these printers can be pricey. But for businesses and serious hobbyists, they’re an investment in creativity and efficiency. As technology improves, you’ll likely see prices drop and capabilities expand.

What would you create if size wasn’t a limit? The future of large-scale 3D printing is full of potential. It’s an exciting time to explore this technology.

One Reply to “Large 3D Printer: Revolutionizing Industrial Manufacturing”

[…] you enjoy working with people, consider a role in sales or communication for 3D printing services. You’ll help clients understand how 3D printing can solve their […]