3D printing can be exciting, but it often comes with challenges. You might encounter issues like warping, stringing, or poor adhesion. These problems can be frustrating, especially when you’re eager to see your creation come to life. Learning how to troubleshoot common 3D printer issues can save you time, money, and headaches.

Many 3D printing problems have simple fixes. For example, if your print isn’t sticking to the bed, you might need to adjust the bed temperature or level it properly. Stringing can often be resolved by tweaking your retraction settings. By understanding these basics, you can quickly improve your print quality.

Remember, every 3D printing enthusiast faces hurdles. Don’t get discouraged if your prints aren’t perfect right away. With practice and patience, you’ll soon be creating high-quality 3D prints like a pro.

Key Takeaways

- Common 3D printing issues often have straightforward solutions

- Regular printer maintenance helps prevent many problems

- Understanding your printer’s settings is key to achieving optimal print quality

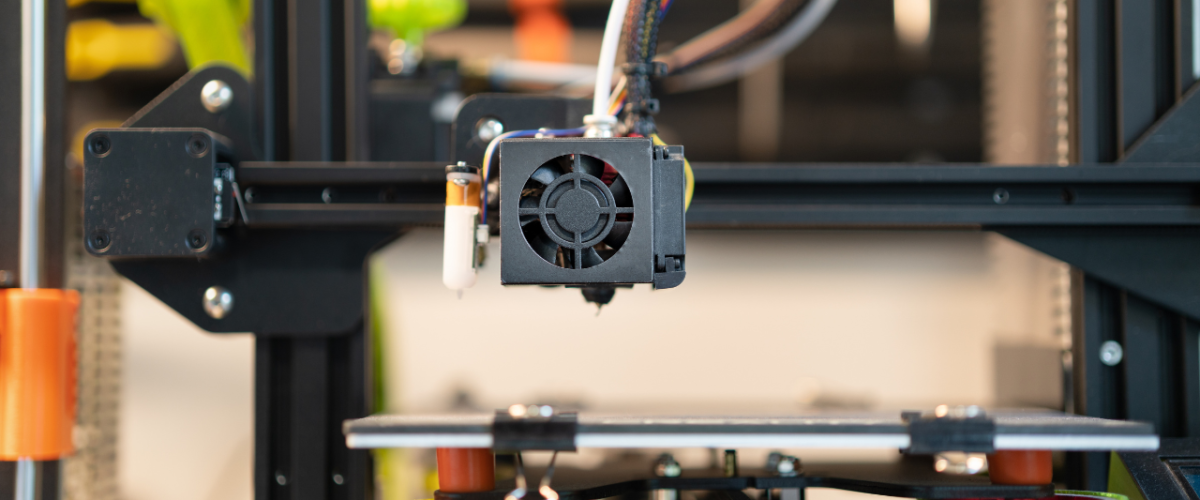

Understanding 3D Printer Components

3D printers have several key parts that work together to create objects. Knowing these components helps you troubleshoot issues and get better prints.

The Extruder and Nozzle Mechanics

The extruder is like the heart of your 3D printer. It pushes the filament through the nozzle to create your print. The nozzle melts the plastic and lays it down in thin layers.

Think of the extruder as a tiny hand squeezing toothpaste. The nozzle is the opening where the paste comes out. Different nozzle sizes affect how detailed your prints can be.

Clogs in the nozzle are a common problem. You can usually fix this by doing a “cold pull” or using a thin needle to clear it out.

Filament Types and Their Properties

Filament is the “ink” for your 3D printer. PLA is the most common type. It’s easy to use and doesn’t warp much.

Here’s a quick comparison of popular filaments:

- PLA: Easy to print, eco-friendly

- ABS: Tougher, good for functional parts

- PETG: Strong and flexible, food-safe

Each type needs different temperatures to print well. Using the wrong settings can lead to failed prints or jams.

Have you tried different filaments? What’s been your experience?

The Importance of the Printing Bed

The print bed is where the magic happens. It’s the surface your object sticks to while printing. A level bed is crucial for good prints.

You can use different materials on your bed to help prints stick:

- Blue painter’s tape

- Glass with hairspray

- Specialized print surfaces

If your prints keep coming loose, try adjusting your bed temperature or using a brim to help with adhesion.

Controlling Print Speed and Temperature

Print speed and temperature are like dance partners. They need to work together for smooth prints.

Printing too fast can cause quality issues. But go too slow, and you’ll be waiting forever for your print to finish.

The right temperature depends on your filament type. Too hot, and you’ll get stringing. Too cold, and layers won’t stick together.

Start with the recommended settings for your filament and adjust from there. Keep notes on what works best for your printer.

Optimizing Print Quality and Consistency

Getting great 3D prints takes skill and know-how. You need to nail the basics and fine-tune your settings for the best results. Let’s look at some key ways to level up your prints.

Achieving Strong First Layer Adhesion

The first layer is crucial for a good print. Clean your build plate with isopropyl alcohol before each print. Adjust the nozzle height carefully – it should be just close enough to slightly squish the filament.

Try using a build plate suited to your material. Glass works well for many plastics. PEI sheets offer excellent adhesion for tricky materials.

Slow down the first layer speed to about 20-30 mm/s. This gives the plastic time to stick properly. Use a brim or raft for extra adhesion on challenging prints.

Heat the bed to the right temperature for your filament. PLA likes 50-60°C, while ABS needs 100-110°C.

Calibration and Leveling Strategies

A level bed is key for even first layers. Many printers have assisted leveling – use it! For manual leveling, the paper method works well. Slide a sheet of paper between the nozzle and bed at each corner. Adjust until you feel slight friction.

Calibrate your extruder steps. This ensures you’re pushing out the right amount of plastic. It’s simple:

- Mark 100mm on your filament

- Extrude 100mm

- Measure what’s left

- Adjust steps in firmware

Check belt tension. Loose belts cause wobbles and shifts in your prints. They should twang like a guitar string when plucked.

Slicer Settings for Optimal Extrusion

Your slicer is where the magic happens. Start with the default profile for your filament, then tweak:

- Layer height: 0.2mm is a good all-round setting

- Temperature: Run a temperature tower to find the sweet spot

- Retraction: 5mm at 45mm/s is a good starting point

- Infill: 15-20% for most parts, more for strength

Print speed affects quality. Slower is usually better, but too slow can cause issues. Try 50-60mm/s for a good balance.

Enable “combing” to reduce stringing. This keeps travel moves within the print.

Troubleshooting Common Print Defects

Stringing? Lower your temperature and increase retraction. A temp tower can help find the right setting.

Blobs on the surface? Check for over-extrusion. Calibrate your e-steps and reduce flow slightly in your slicer.

Layer shifts? Tighten your belts and check for loose screws on your print head.

Warping? Use a brim, increase bed temperature slightly, and ensure your print area is draft-free.

Gaps between infill and walls? Increase your overlap settings in your slicer.

Remember, each printer is unique. Keep notes on what works for you. With patience and practice, you’ll be printing like a pro in no time!

Maintenance and Troubleshooting

Keeping your 3D printer in top shape requires regular care and quick problem-solving. Let’s explore how to prevent issues, clear clogs, and fix common printing problems.

Preventive Maintenance for Longevity

You should clean your printer regularly to avoid build-up. Wipe down the build plate after each print. Use a soft brush to remove debris from the extruder and nozzle.

Check belts and pulleys monthly. Tighten loose belts and replace worn ones. Lubricate moving parts with machine oil to reduce friction.

Calibrate your printer often. This includes leveling the bed and adjusting the nozzle height. A well-calibrated printer produces better prints and lasts longer.

Update your firmware when new versions are available. This can improve performance and fix bugs.

Identifying and Addressing Clogs and Jams

Clogs in the nozzle can ruin prints. If filament stops flowing, your nozzle might be clogged. Try a “cold pull” to clear it. Heat the nozzle, push filament through, then let it cool and pull it out.

For stubborn clogs, use a cleaning needle. Heat the nozzle and carefully insert the needle to dislodge debris.

Jams in the extruder are also common. If the filament isn’t feeding, check for tangles or breaks. Clear any obstructions and reload the filament.

Keep spare nozzles on hand. Sometimes it’s easier to replace a clogged nozzle than to clean it.

Solving Retraction and Warping Issues

Retraction problems can cause stringing or oozing. Adjust your retraction settings in your slicer. Increase retraction distance and speed slightly until the issue improves.

Use a temperature tower to find the best printing temperature for your filament. This can reduce stringing and improve overall print quality.

Warping occurs when parts of your print cool too quickly. Use a heated bed for materials prone to warping. Apply a thin layer of glue stick or hairspray to the bed for better adhesion.

Try printing with a brim or raft to increase surface contact with the bed. This can significantly reduce warping on larger prints.

Conclusion

3D printing can be tricky, but don’t let that discourage you. With practice and patience, you’ll become a pro at tackling common issues. Remember to check your printer’s settings regularly and keep it clean.

When problems arise, take a deep breath and approach them step-by-step. Start by identifying the root cause before jumping into solutions. This approach will save you time and frustration in the long run.

Keep learning and experimenting with your 3D printer. Each challenge you overcome makes you a better maker. And don’t forget – the 3D printing community is full of helpful people. Reach out if you’re stuck.

Lastly, celebrate your successes, no matter how small. Every perfect print is a victory. Happy printing!